Die Springs Because of their high durability to stress and force, die springs are often ideal for many different industry applications. Mid-West Spring and Stamping specializes in creating custom die springs for customers to meet their specific project and industry...

Blog

What are Constant Force Springs?

Constant Force Springs Constant force springs may be seen as basic, but they have a seemingly endless list of applications and uses. At Mid-West Spring and Stamping, we can customize your perfect constant force spring for your specific application, adhering to strict...

Suspension Springs: Everything You Need to Know

Suspension Springs Suspension springs are crucial to a vehicle's lifespan and ease of use. MidWest Spring and Stamping works alongside all of our customers to provide tailored solutions to meet each individual need. Our highly skilled team of professionals offers a...

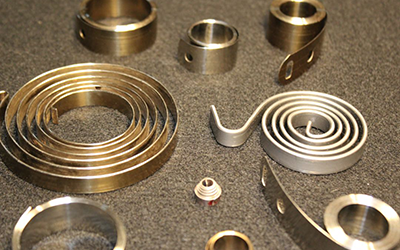

Custom Torsion Springs: Create the Right Torsion Spring for Your Application

Torsion Springs Torsion springs are widely used in both everyday and industrial items where rotating force is required such as garage doors, door hinges, and various types of machinery and equipment. Torsion springs provide high torque and can be manufactured in a...

Custom Compression Springs

Compression Springs Compression springs have applications in several industries that people use in their everyday lives today. Produced in a range of shapes, materials, and sizes, compression springs are what most people think of as a “standard spring.” Mid-West...

Extension Springs: Types, Uses, and Customization

Extension Springs An extension spring is designed to store and absorb energy through the use of either hooks or loops, depending on the spring’s final application. At Mid-West Spring and Stamping, we work with our customers to custom design extension springs for a...

HOW SHOT PEENING INCREASES THE LIFESPAN OF YOUR PART

Shot Peening Strength and performance matter when it comes to the integrity of parts and spring components. Through the process of shot peening, the service life of a component can be extended by increasing resistance to fatigue. By understanding how shot peening...

Select the Right Material for the Right Part

Spring Materials Specific spring materials are tailored for their specific applications. You would not use the type of spring found in a ball point pen in an automotive application. Once you learn the different spring materials available, you can start making the best...

Choosing the Best Material for Custom Made Springs

Custom Designing Springs At Mid-West Spring and Stamping, we know the importance of being informed and we always aim to provide our clients with the tools necessary to make important project decisions every step of the way. When it comes to custom designing springs...