Constant Force Springs

Constant force springs may be seen as basic, but they have a seemingly endless list of applications and uses. At Mid-West Spring and Stamping, we can customize your perfect constant force spring for your specific application, adhering to strict tolerances and project budget requirements.

How are Constant Force Springs Designed?

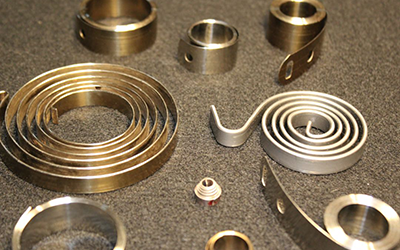

Constant force springs are designed by wrapping a flat piece of metal, usually steel, around a drum or by coiling a metal ribbon around itself, maintaining a constant radius. This design adds tension to the spring and when a load moves against it, the spring moves a short distance in a circular direction. The width and thickness of the spring metal used, as well as the diameter of the outermost coil, directly impacts the load rating.

The spring gets its name because its force value in its loaded state compared to its resting state is almost the same, with the difference considered negligible. The spring’s force is thereby deemed “constant” because it remains consistent throughout.

Common Applications for Constant Force Springs

Because of their versatility and consistency, constant force springs have several uses and applications in a variety of industries. Their unique qualities provide a dependable and efficient force that can be used to move both heavy and light objects. Constant force springs have a reputation for longevity and durability because of how well they maintain force loads.

Common uses and applications for constant force springs include:

- Small Medical Devices

- Heavy Door Retraction

- Gym Equipment

- Toys

- Hairdryers

How Do You Choose a Constant Force Spring?

Constant force springs are an ideal choice for any application involving counterbalances and long-motion functions. The experts at Mid-West Spring & Stamping will work with you to understand your spring requirements and final project application to guide you to the best possible constant force spring materials, sizes, finishes, and machining processes.

We offer various capability options to manufacture customer constant force springs including:

- Material .004″ to .125″ thick & up to 5″ wide

- Various wire materials

- Efficient CNC machining

- Secondary processes & finishes

- Engineering assistance with spring designs

Our team of experienced engineers and technicians is ready to work with you to create your custom constant force spring for your next project. Since 1928, we’ve specialized in designing and manufacturing custom springs to meet every customer’s need, so we’ve seen it all.

Want to get started on your constant force spring project? Request a quote now!