Different applications require different springs, and those springs often need different finishings. It is not rare to see a spring with an open end, but your application may require the springs to be flat on both ends. That is where spring grinding comes into play.

Just as springs can have different finishes, springs can have different ends. Along with the open-ended spring, there are also open and ground ends, closed and non-ground ends, and closed ends that are both squared and ground. Compression springs have these options available to help them become more versatile and to be used in many other applications.

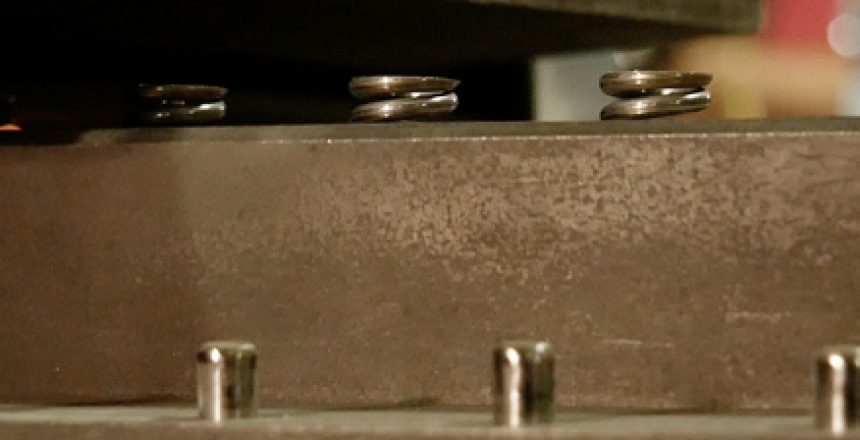

Springs are considerably cheaper without grind, but the grinding adds to the successful function of the spring. The process can happen in a couple different ways, but when a compression spring’s ends need to be flattened, an automatic grinding machine is likely to be used. The bushing, or the component that holds the spring in place, is fitted into a round plate, and that leaves a small quantity of spring sticking out on both ends.

The plate will turn itself slowly, allowing both bushing and spring to pass between a pair of grinding wheels. Those wheels will grind the ends to their required flatness, then drop them into a box with the other completed springs.

If the spring is perfectly square, then there will be no gap as you inspect the spring and reverse it around. Even if there is a small gap, the spring will still flatten under load.

Whatever your application needs, allow Mid-West Spring and Stamping to help with your spring grinding requirements. As a premier custom springs manufacturer, we craft compression springs in a variety of compression types, shapes, and materials to your individual specifications.

Mid-West Spring and Stamping is committed to creating more value for our customers with fewer resources through continuous improvement and the elimination of waste. Join the multitudes of customers that rely on us to optimize the fit, form, and function for their desired outcomes at a competitive cost. Request a quote today, or call us at 800-424-0244.