P = F * R or Load = deflection times Rate

Example: A compression spring has a Rate of 103 #/in. If the spring is pushed (deflected) .660”, what will be the resulting load?

P = .660” * 103 #/in

P = 67.98#

Here is an example of some requirements that could be shown on a typical compression spring blueprint.

Load: 67.98# +10% at 1.520”

Rate: 103 #/in +10%

Free length: 2.180”

Now that we know the Rate requirement, how do we test? A standard Rate test requires that the spring be preloaded to 20 percent of its total potential deflection, and then deflected another 60 percent of that potential deflection. The reason for this is simple: It allows travel throughout 80 percent of the total deflection of the spring. To test a spring correctly, two heights must be used. Here is where the mystery comes in.

Many people do not understand why it is necessary to use two heights to verify Rate. Since Rate is the load per deflection, it should only be necessary to deflect to ANY height, record the load at that height, and then calculate the Rate.

By formula, this would be correct. However, there is one issue that doesn’t get taken into account with this scheme — the variation in free length. When production quantities are involved or 100 percent testing is required, a standard method of Rate testing is needed.

So, what does the variation in free length have to do with a Rate test, since Rate has nothing to do with the spring pitch? It has to do with the inherent variation in free length from both coiling and grinding.

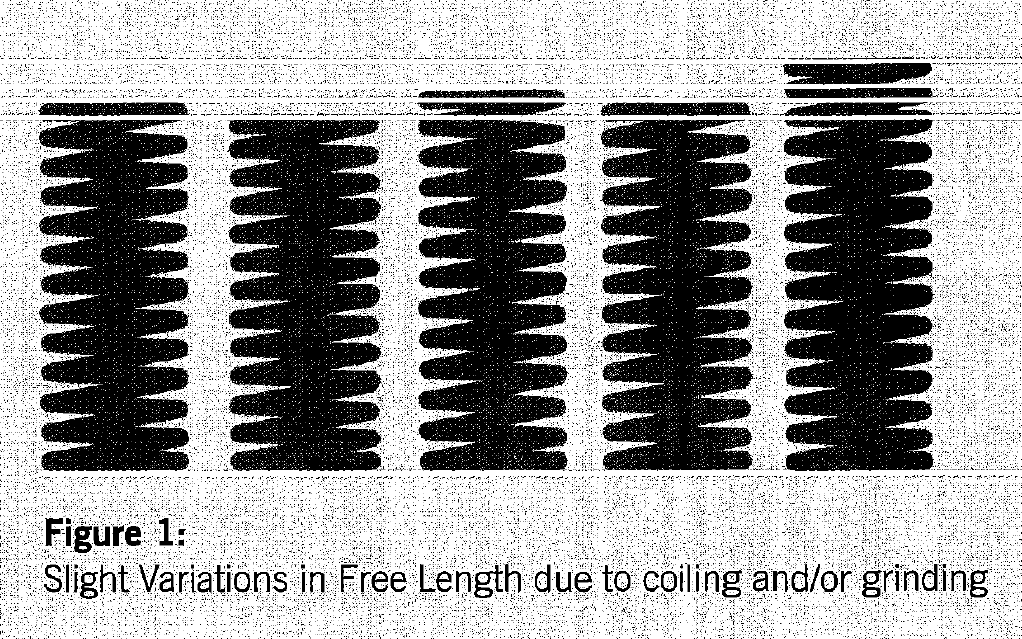

In today’s spring houses, most coiling machines use free length gaugers that monitor the free length of each spring. This method allows sorting and elimination of springs that may not meet the free length requirement. However, this still doesn’t mean each spring is exactly the same length when it drops from the coiler. The gaugers are set to pass only conforming parts and scrap the rest. If the ends are ground, free lengths will vary, somewhat. The result could be as shown in Fig. 1. The five springs have slightly different free lengths, even though they were processed on the same coiler and the same grinder. This example is not only typical, it’s expected on a formed product.

With this example of five springs with slightly different free lengths, preloading to a height means each spring would have a slightly different preload. By preloading to a load, and not a height, you keep the Rate testing consistent by always starting at the same base preload. A typical Rate test for the spring in this example, with a 10 percent tolerance, would be as shown.

As you can see, every spring tested will begin at the same 25.0#, and then travel the same additional deflection of .700”. If the load reading is within the two loads shown, the spring Rate is within the +10 percent requirement.

One caution: Testing the Rate of a spring does not insure the loads are correct at the required height(s). Unlike Rate, loads are a function of pitch. It is wholly possible for the Rate to be correct, but the load(s) to be out-of-tolerance. Free length must be held within a specified tolerance for the loads to be correct.

By: Randy DeFord, Engineering Manager Mid-West Spring & Stamping